Product for Agricultural, Livestock and Marine Purposes

Cooling/Heating SCO System

Differentiated Technical Prowess

Efficiency Verified on Site

Cooling/Heating SCO System

Efficiency Verified on Site

Cooling/Heating SCO System

Application of Differentiated

Smart Farm Technology

Smart Farm Technology

The temperature, humidity and weather situation are monitored

through the application of smart farm technology,

and only the minimum energy costs are used to

provide the optimized crop growth environment required

for crop quality enhancement and productivity enhancement.

through the application of smart farm technology,

and only the minimum energy costs are used to

provide the optimized crop growth environment required

for crop quality enhancement and productivity enhancement.

Korea’s First

2-year Remote Control

2-year Remote Control

Since an optimized system suitable for the field conditions of the place of installation is operated for quality enhancement and harvest rate enhancement, a 2-year remove control system is operated to provide convenience.

Power Consumption Control that Adds Economic Feasibility to SCO System

Since the PI(proportional control) temperature control is used to precisely control the power consumption according to the crop cultivation conditions per region and to the selected temperature, the electricity cost can be reduced through maximizing the cooling/heating performance and minimizing the unnecessary power consumption.

Safety Secured through Application of Various State-of-the-art Sensors

The outdoor temperature, indoor temperature and air blasting temperature standards are precisely digitized and applied per crop cultivation, and the outside weather changes are detected to

provide the optimized growth environment.

Stabilized even temperature maintenance

Stabilized even temperature maintenance

There is no risk of condensation or fog.

There is no risk of condensation or fog.

Effective prevention of various damages by blight and harmful

Effective prevention of various damages by blight and harmful

insects

provide the optimized growth environment.

insects

Convenient Control Regardless of Place

A smartphone remote control system to which the IoT technology is applied

can be utilized to enjoy your smart life regardless of place and time.

can be utilized to enjoy your smart life regardless of place and time.

Multiple Safety Devices

Optimized for Crops

Optimized for Crops

An excellent safety design consisting of smart auto control, earth leakage breaker, overheating safety sensor, water level sensor, vibration sensor, anti-sticking function, anti-freeze function, etc. protects the growth environment of your crops.

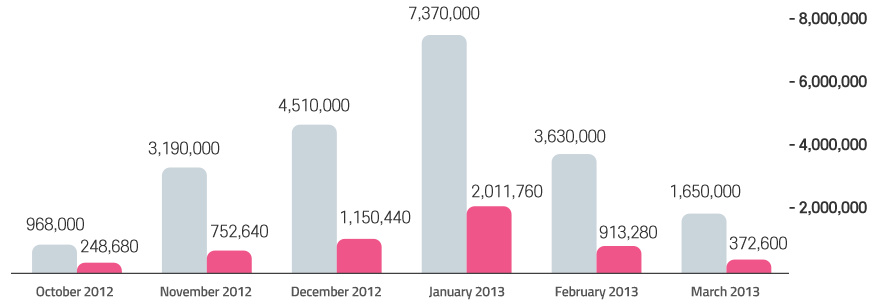

Oil, Compared to Products

Manufactured by Other Companies

Manufactured by Other Companies

Price Used Diesel : Liter(ℓ) : 1,100 won

Price Used Diesel : Liter(ℓ) : 1,100 won Price Used KW : 40 won(agricultural-purpose electricity)

Price Used KW : 40 won(agricultural-purpose electricity)Comparison between Prices Used

[Flowering Plant Farm, Eumseong, Chungcheongbuk-Do]]

Because RAONIS has confidence

in its products, RAONIS is capable.

in its products, RAONIS is capable.

Customer Service Taking Responsibility to the Last

RAONIS provides a year-round call-in help service.

Products Produced

Optimized Made-to-order Production Suitable for Crop Environment/Facility Condition

Low-temperature Crop : Below 15℃

Heated Pyeong |

Auxiliary Heating |

Power Consumption |

| 500 | 35,000Kcal | 50Kw/h |

| 500~1,000 | 35,000Kcal | 100Kw/h |

| 1,000~2,000 | 70,000Kcal | 200Kw/h |

| 2,000~4,000 | 100,000Kcal | 400Kw/h |

* The power consumption may vary depending on the crop kind, insulation status and floor level.

High-temperature Crop : Below 15℃~20 ℃

Heated Pyeong |

Auxiliary Heating |

Power Consumption |

| 50~300 | 35,000Kcal | 50Kw/h |

| 300~600 | 35,000Kcal | 100Kw/h |

| 600~1,000 | 100,000Kcal | 200Kw/h |

| 1,000~2,000 | 200,000Kcal | 400Kw/h |

Reduced maintenance cost, temperature maintenance, control convenience, etc.

SCO system already verified on site

SCO system already verified on site

Installation case (Approximately 80 1000-pyeong places in operation nationwide)

2000-pyeong Flowering Plant Market in Eumseong,

Chungcheongbuk-do Operated by Chunbcheongbuk-do

Regional Public Procurement Service

Chungcheongbuk-do Operated by Chunbcheongbuk-do

Regional Public Procurement Service

1000-pyeong Flowering Plant Distribution Complex

in Eumseong, Chungcheongbuk-do

in Eumseong, Chungcheongbuk-do

2400pyeong Tomato Breeding Project in Jeollabuk-do

Recommended Place of Installation

Facility House

Swimming Pool

Large-scale Fish Farm

Hotel, Membership Resort,

Training Institute, Etc.