Dry Heating Panel

Construction Procedures

Simple construction

Warm heating

Low price

Thorough customer service

Warm heating

Low price

Thorough customer service

Construction easy enough

to be carried out by any person!

You are not required to be a construction specialist to be able to conduct this construction.

to be carried out by any person!

You are not required to be a construction specialist to be able to conduct this construction.

The construction can be completed on that day,

and heating can be initiated on that day as well!

and heating can be initiated on that day as well!

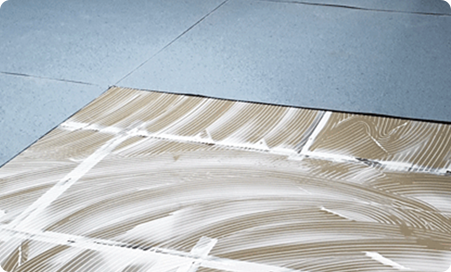

1. Cleaning and Construction of Floor Adhesive

(the amount of adhesive to be applied : 3.3㎡EKD 300~500g required)

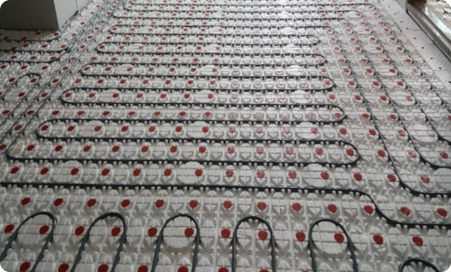

2. Installation of EPS Module Sheets

Tip : You could use a cutting knife to easily cut the corners or pieces required during construction.

3. When installing the heating pipe

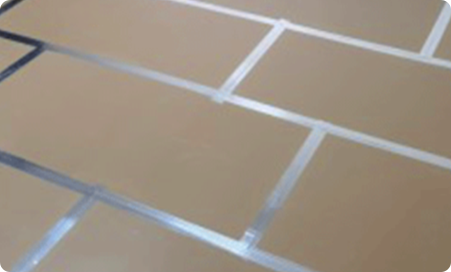

4. Heat Sink Construction/Aluminum Tape Construction

The construction ceramic heat sink has a measurement of 1800mm(width)X900mm(length)X5mm(thickness), and plays a role to distribute the upper load, to diffuse heat and to store heat. Since it can be easily cut with a cutting knife according to the construction structure and shape, it enables convenient construction.

Tip : Since the galvanized heat sink has a thickness of 0.5mm, its strength is heat diffusion and its weakness is load distribution. Therefore, it is recommended that it be used for SPC reinforced floor board installation only.

Tip : Since the galvanized heat sink has a thickness of 0.5mm, its strength is heat diffusion and its weakness is load distribution. Therefore, it is recommended that it be used for SPC reinforced floor board installation only.

5. Connecting Heating Pipe to Distributor

Tip :When constructing a space that is less than 3 pyeong, using a Y-shaped pipe connecting socket(external diameter: 10mm) instead of a distributor to partitively construct the heating pipes will activate the flow of heating water, will enhance the heating speed, and will enhance the durability by applying less strain to the pump.

References : When utilizing floor-sheet or PVC deco-tile finishing

Fiber Protecting Sheet Construction

Using a galvanized heat sink generates heat during floor-sheet or deco-tile finishing and causes the floor sheet or deco tile to contract and expand, resulting in wrinkles

and joint gaps. To prevent such results, a fiber protecting sheet is constructed.

During the construction, maintain a 10mm gap from the wall and a 4mm gap between the fiber protecting sheets, and complete the gap finishing with aluminum tape.

Using a galvanized heat sink generates heat during floor-sheet or deco-tile finishing and causes the floor sheet or deco tile to contract and expand, resulting in wrinkles

and joint gaps. To prevent such results, a fiber protecting sheet is constructed.

During the construction, maintain a 10mm gap from the wall and a 4mm gap between the fiber protecting sheets, and complete the gap finishing with aluminum tape.

6. Finishing Material Construction(separately purchased product) - Floor Sheet, Floor Board, Etc.

or PCV tile finishing.

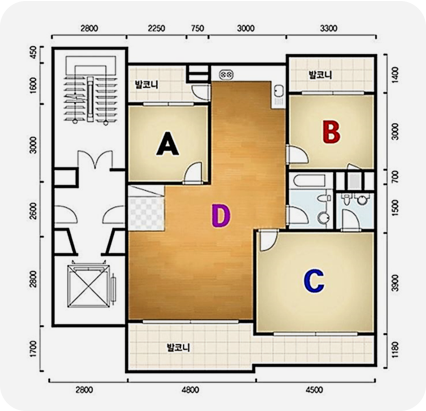

How to calculate pyeong per material to be purchased

How to calculate pyeong(when constructing Heating/Finishing Materials A, B and C)

A : 3m x 3m = 9m2

B : 3.3m x 3m - 9.9m2

C : 4.5m x 3.9m - 17.77m2

A + B + C ( 9.0m2 + 9.9m2 + 17.55m2 - 36.45m2)

= 36.45m2 x 0.3025 = 11.02pyeong(actual pyeong)

-36.45m2/3 = 12.15pyeong(pyeong to be purchased, including loss%)

Recommended Place of Installation

Hospital/Health care facility

Office, Factory lounge

Lodging Facility

Religious Facility

Green Living Facility

Housing Complex