Technology

Outline of Technology

Outline of TCM Solution

"CHANGE"

TCM Solution is a new transparent thin film conductor that will replace the pre-existing ITO thin film material and metal heating element, and is a new future-oriented electric/electronic component material that is highly applicable to not only the transparent electrode field, but also to a wide range of industrial sectors based on its diverse functions such as semi-conductor transparent high-temperature heating element, electro-magnetic absorption heating, electro-magnetic interference and infrared reflectance.

Optical transparency penetrating 85% of the visible light wavelength

Optical transparency penetrating 85% of the visible light wavelength Formation of ultra-thin film with a coating thickness of 1㎛~10㎛

Formation of ultra-thin film with a coating thickness of 1㎛~10㎛ Transparent thin film conductor having a resistance value ranging from 10Ω to 100Ω/㎠

Transparent thin film conductor having a resistance value ranging from 10Ω to 100Ω/㎠ It has an approximate surface strength of 7H, is highly scratch-resistant, and has no disconnection

It has an approximate surface strength of 7H, is highly scratch-resistant, and has no disconnection Thanks to its diverse functions such as transparent electrode, display(inorganic EL material), electro-magnetic interference, electro-magnetic absorption heating and transparent antenna,

Thanks to its diverse functions such as transparent electrode, display(inorganic EL material), electro-magnetic interference, electro-magnetic absorption heating and transparent antenna,

it can be applied as a basic material component. It is highly acid-resistant, alkali-resistant and salt-resistant, and its excellent durability allows it to be used semi-permanently.

It is highly acid-resistant, alkali-resistant and salt-resistant, and its excellent durability allows it to be used semi-permanently.

Outline of Semi-conductor Transparent High-pressure Heater

"RAONIS leads the industry with its differentiated technical prowess"

After using the spray method to thin-film-coat the TCM solution onto the surface of heat-resistant materials such as ceramic, quartz glass and parka glass under the atmospheric

After using the spray method to thin-film-coat the TCM solution onto the surface of heat-resistant materials such as ceramic, quartz glass and parka glass under the atmospheric

condition, Silver is fired and electricity is applied to process a semi-conductor transparent high-pressure heating element that stably reaches an instant temperature above 500℃.

Silver is fired and electricity is applied to process a semi-conductor transparent high-pressure heating element that stably reaches an instant temperature above 500℃. It is applicable to industrial sectors involved in manufacturing diverse products that require heater heat sources at a temperature below 600℃ such as kitchen appliances, household

It is applicable to industrial sectors involved in manufacturing diverse products that require heater heat sources at a temperature below 600℃ such as kitchen appliances, household

appliances and heating products.

TCM (Transparent Conductive Materials ) Heater Process

Production of

TCM Solution

TCM Solution

Heat-resistant

Material Surface/

Thin Film Coating

Material Surface/

Thin Film Coating

Firing of Silver

Semi-conductor

High-temperature

Transparent

Heating Element

High-temperature

Transparent

Heating Element

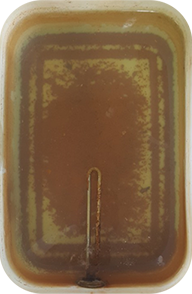

Characteristics of Semi-conductor Transparent High-Temperature TCM Heater

insulating material

Silver

TCM-coated thin film

quartz tube

Semi-conductor Transparent High-pressure TCM Heater Capable of Replacing Metal Heater

It causes no oxidation corrosion.

It causes no oxidation corrosion. It produces no scale through far-infrared(above 90%) radiation.

It produces no scale through far-infrared(above 90%) radiation. It has no disconnection and is highly heat-efficient.

It has no disconnection and is highly heat-efficient. It reduces energy by approximately 10% compared to a metal heater.

It reduces energy by approximately 10% compared to a metal heater. It is highly acid-resistant, alkali-resistant, salt-resistant and scratch-

It is highly acid-resistant, alkali-resistant, salt-resistant and scratch-

resistant. It requires no maintenance cost resulting from heater replacement.

It requires no maintenance cost resulting from heater replacement. Its excellent durability makes it possible to use it semi-permanently.

Its excellent durability makes it possible to use it semi-permanently.

Comparison between TCM Heater and Metal Heater

TCM Heater |

|

Flange Heater |

Specifications of TCM Heater

| Division | Characteristics | |

| Transparency | ≥ 90% (Transparency varies depending on the visible light area and coating layer thickness.) | |

| Coating Density | Is adjusted according to the TCM compounding ratio and coating layer thickness : 0.1~8.0 W/㎠ | |

| Resistance Value | Ranges from 10Ω to 100 Ω/㎠. | |

| Thin Film Coating Thickness | 0.1~10 μm (500Å~9000Å) | |

| Coating Surface Strength | 7H | |

| Efficiency | ≥ 95% | |

| Principle of Heating | Conductor Resistance and Indirect Radiative Heating | |

| Applicable Material | All Non-conductive Materials (glass, ceramic, fiber, pottery, etc.) | |

| Coatable Size | Tube | No Limitation |

| Flat Plate | No Limitation | |

| Etc. | No Limitation | |

| Corrosion Resistance / Scratch Resistance | Very Strong (application of coating layer post-processing technology) | |

| Applicability | It can be applied as a basic material component, since it features diverse functions such as transparent electrode, display(inorganic EL material), electro-magnetic interference, electro-magnetic absorption heating and transparent antenna. | |